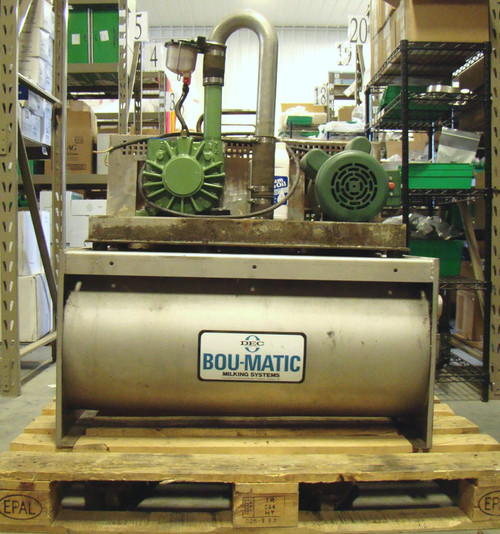

Compact permanent install vacuum pump. Milk 4 or 5 bucket units.

(note the main picture shows the GEA pump, but this listing is for the Masport version)

System Includes;

- New 2 HP 230 volt TEFC motor

- New Masport M2 vacuum pump with oiler

- Used stainless steel balance tank (Bou-Matic)

- 1-1/2 inch NPT vacuum line connections.

M2 Pump capacity 25-30 CFM @15" Hg

M2 Pump RPM recomended from 1200 to 1700

Footprint dimensions; 18 inch Width x 32 inch Length x 20.5 inch Height

Features a Long Life Masport M2 rotary vane vacuum pump Designed for smaller milking systems.

The tank helps protect the pump from liquids in case of running over a bucket and levels out the air flow for stable teat end vacuum. Pump comes with a belt guard for safety

To install:

1. Locate the unit in a convenient place. Best location is in an equipment room with a drain - separate from where you milk.

2. Plumb the pvc vacuum line to the vacuum balance tank. The vacuum line should be 1.5" or larger and looped. Use pipe tees with a plug in one opening instead of using elbows in the furthest corners. This allows for better access for cleaning and checking air flow. (see drawing in detail images)

3. Install a stall cock on this vacuum line at each place a bucket milker will be operating. Many customers milk two cows or goats at each stall cock. For a small herd of cows, 2 buckets and 4 stanchions or 3 buckets and 6 stanchions is the most efficient set up. 3 cow bucket milkers is the maximum that one person can handle and do a good attentive job of milking.

4. Install Automatic vacuum line drain valves at all low points or where risers are used on the vacuum line.

5. Install the pump exhaust to the outside of the building. The exhaust will have some oil residue and is best vented outside the building.

6. Wire the electric motor.

7. Add oil to the reservoir on top of the pump and you are ready to milk.

Items not included that you will need:

- Vacuum Regulator - 1.5K recommended

- Vacuum Gauge for milking room 7135 or 7145

- Vacuum Gauge for Pump room 7135 or 7145

- Schedule 40 PVC pipe and fittings to build the vacuum line (Purchase locally)

- Remote Switch for Electric Motor - a remote On/Off switch will make it handier to start and stop the pump. (our part number 7900 or Purchase locally)

- Hangers for the pvc vacuum line. Item 1060-142 recommended.

- Stallcocks to connect each bucket milker to the vacuum system. order 1 per bucket unit and 1 xtra if you have a claw/hose washer (56200) Stallcock item numbers are 23855, 23856, 23857, 1060-251

- Line drain. All milking systems move wet air and moisture will accumulate. Add an automatic line drain to the end of the line away from the pump and any spot where moisture might collect and can't get to a drain. Vacuum line drain item number: 3420004

compare to Conde 1VS6SS2 7602GEA

Ships from Hamby Dairy Supply in Missouri by LTL freight only.

It is not UPS Shippable.. Please call for shipping quote.

Free Pickup available -

Higher capacity 3 hp version available

M2 rebuild kit normally in stock

M2 replacement pump heads normally in stock

Belts available at any local hardware store.

Related items;

7602 Conde 2 hp vacuum system

7603 Conde 3 hp vacuum system

7606 Conde Vapor Oil SS Super 6 vacuum pump head

7601 Rebuild kit for Model 6 Conde vacuum Pumps

Assembled In USA

Updated April 2024